Chinese Compressor Co buys a Holroyd Helical Profile Grinder

Date published: 29 March 2016

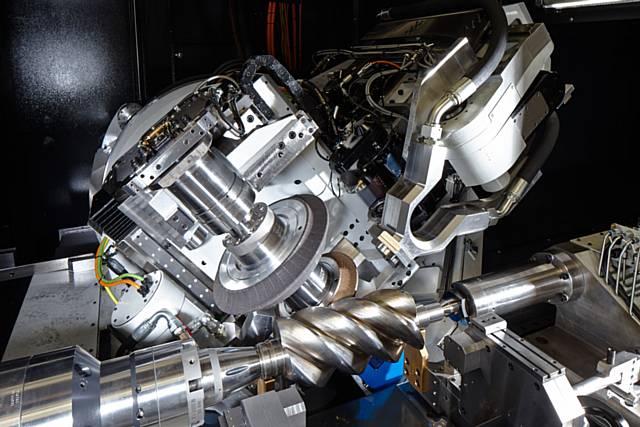

Holroyd Precision Zenith 400

Precision Technologies Group company, Holroyd Precision Limited, is to supply one of its ultra-precise Zenith 400 helical profile grinders to one of China’s premier air compressor manufacturers.

Costing in excess of £1 million, the Zenith 400 will be equipped with Holroyd’s proprietary twin grinding wheel system. Scheduled for shipping to China’s Zhejiang province in September 2016, the machine will be used to precision-grind air compressor rotors.

Launched at EMO Hannover 2011, the Zenith 400 helical profile grinder very quickly caught the eye of screw compressor manufacturers seeking superior, ultra-precise grinding solutions and has gone on to secure £multi-million sales for the Rochdale-based business.

A key attribute of the Zenith 400 lies in the fact that it is the only helical profile grinding machine with the capability to use aluminium oxide, ‘diamond hard’ plated Cubic Boron Nitride (CBN) and vitrified, dressable CBN grinding technologies – effectively providing roughing and finishing capabilities on one machine.

With the advantage of twin grinding wheels, the air compressor manufacturer will be able to complete both rough- and fine-grit (finishing) grinding in one seamless operation. By using CBN grinding wheels for both grinding processes, they will also benefit from considerably faster grinding speeds, significantly reduced cycle times, improved heat dissipation, and – thanks to the greater resistance of CBN – much longer wheel life, with no need for dressing – even at high stock removal rates.

“We are extremely pleased to have received this significant machine order from such a prominent air compressor specialist,” comments Holroyd Precision Limited’s Sales Manager, Mark Curran. “The twin grinding wheel capability of the machine was clearly a major attraction to the customer and, once the machine is installed, we look forward to reporting on the production efficiencies that they have been able to achieve.”

The Zenith 400 helical profile grinder represents a whole new generation of grinding technology and capability from Holroyd Precision Limited, a company with a reputation for producing the world’s most accurate rotors, gears, threads plus ultra precision components.

Encompassing advanced innovations and a new control system that incorporates development and production software, Zenith 400 models have been designed to suit all user requirements, in either research and development or mass production.

Holroyd Precision has also developed a process whereby plated CBN can be used for rough grinding, after which a vitrified CBN finishing wheel can be used on the same arbor. “This newly developed technique means we can use high-efficiency plated CBN for rough grinding and the versatility of the vitrified CBN process for finish grinding,” adds Mark Curran. “The vitrified CBN enables us to change the shape of the wheel and also re-dress the wheel in light of any wear.”

Developed to precision grind components weighing up to 700kg and measuring up to 420mm in diameter and 2.2 metres in length, the Zenith 400 combines high stock removal rates and aggressive semi-finishing, with production rates and accuracies tailored to the most demanding of manufacturing strategies.

Key features of Zenith 400 helical profile grinding machines include:

- Vitrified Al2O3, vitrified CBN and plated CBN grinding wheel options

- Accelerated set-up, with fully automated grinding wheel balancing system

- Powerful, menu-driven touch screen programming

- High stock removal rates, aggressive semi-finishing and precision fine finishing

- Holroyd’s unique on-board 3D CMM component scanning probe with full automatic compensation feedback

- High speed spindles and advanced in-process dressing systems to maintain profile accuracy and keep the grinding wheel in optimum condition

- Complete integration with automated parts handling systems

Incorporating the brands of Holroyd, Binns & Berry, Crawford Swift and Holroyd Precision Components, PTG has established itself at the forefront of high precision machine tool design, build and supply. The PTG range includes ultra precision grinding machines for rotor, thread and gear operations; rotor milling machines; heavy duty lathes; deep hole boring machines; friction stir welding machines and special purpose machine tools for the manufacture of precision components. Industrial sectors served range from aerospace, medical and mould tool & die to marine, power generation, mining, oil & gas, steel, high end and heavy automotive.

Do you have a story for us?

Let us know by emailing news@rochdaleonline.co.uk

All contact will be treated in confidence.

Most Viewed News Stories

- 1Drugs and cash seized during morning raids at suspected stash houses

- 2Middleton school hails another outstanding inspection result

- 3Ogden family announces intention to invest £2m in Rochdale AFC

- 4Former councillor and hospital campaigner Jean Ashworth has died

- 5Man convicted after police car filmed driving dangerously in Kirkholt

To contact the Rochdale Online news desk, email news@rochdaleonline.co.uk or visit our news submission page.

To get the latest news on your desktop or mobile, follow Rochdale Online on Twitter and Facebook.