High tech 3D printer at North Manchester General Hospital to revolutionise treatment

Date published: 14 September 2017

High tech 3D printer at North Manchester General Hospital to revolutionise treatment

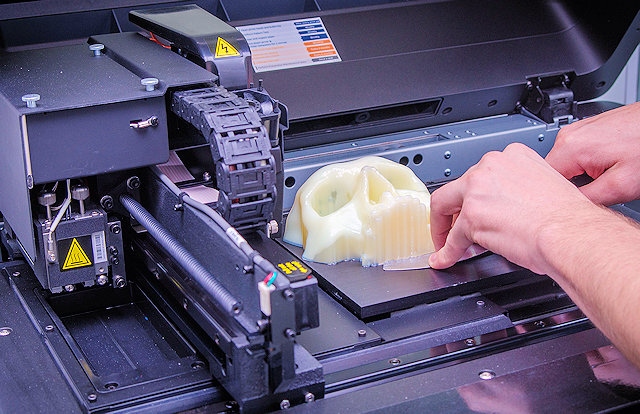

Patients at North Manchester General Hospital will benefit from the production of high tech implants and prostheses with the touch of a button on a 3D printer.

The maxillofacial laboratory at North Manchester General Hospital has spent £38,000 in a 3D printer and £20,000 in software packages to house the first 3D printer in an NHS hospital in Manchester to be used directly to treat patients.

The Statasys Objet 30 3D printer purchased from Tri-Tech 3D with Materialise 3D surgical planning software will help to reduce the surgery time and length of anaesthesia for patients, improve surgical outcomes and facilitate better understanding for patients about the procedures they are undertaking.

The printer works by using scans of the patient and then creating a virtual 3D model of them. Surgeons and reconstructive scientists are able to plan patient specific devices in virtual reality before they go to the design stage. The prosthesis, bars or plates are then created by the printer layer by layer by using metal or plastic compounds to build up the product. The final stage of the project sees the product sterilised before it is passed on to be used on the patient.

Oliver Burley, reconstructive scientist/maxillofacial laboratory manager, said: “The 3D printing service will be run by the team of reconstructive scientists and dental technicians. Its main purpose will be to assist the oral and maxillofacial consultants in treating and restoring patients who have undergone resection for management of disease (predominantly cancer), suffered facial trauma, or have congenital anomalies.

"This requires pre-surgical planning to facilitate accurate plates and bars which are designed specifically for individual patients by matching their unique anatomy. Previously we would have had to create a model of the device by using external companies which typically took in excess of two weeks. Now the 3D printer is based in-house, we are able to design and manufacture a variety of medical devices within hours.

“Some devices are printed from a standard design to make multiple identical copies of the same device. Other devices, called patient-matched or patient-specific devices, are created from a specific patient’s imaging data.”

Andrew Baldwin, consultant maxillofacial surgeon and divisional clinical director for surgery at North Manchester General Hospital, said: “North Manchester General Hospital has one of the largest head and neck cancer centres in the region, so it is very important that the latest practices and technology are utilised. With increasing demands and expectations, there is a need for a better quality service to provide patients with the best possible care. Within medicine, the oral and maxillofacial specialty has led the way in embracing 3D technologies.”

It is hoped that over time the 3D printer will be utilised for other specialties alongside oral and maxillofacial. These will include: ENT, orthodontics, orthopaedics, cardiology, cardiothoracic, ophthalmology, breast care, renal, dermatology and maternity.

Do you have a story for us?

Let us know by emailing news@rochdaleonline.co.uk

All contact will be treated in confidence.

Most Viewed News Stories

- 1Royton haulage firm fined after Rochdale dad went to work and didn’t come home

- 2Six men arrested in Rochdale child exploitation investigation

- 3Newhey's Char Steakhouse and Bank Chamber close with immediate effect

- 4Two men arrested after police chase ends up in Middleton river

- 5Obituary: Jean Ashworth

To contact the Rochdale Online news desk, email news@rochdaleonline.co.uk or visit our news submission page.

To get the latest news on your desktop or mobile, follow Rochdale Online on Twitter and Facebook.